SKD LED Lighting Comprehensive Guide

In the international trade of B2B form, the terms CBU, SKD, CKD, and so on are often heard. Such terms originated in the automobile industry and represent the form of transportation of goods on the way.

CBU (Completely Built Up), as the name suggests, refers to the finished goods. When the buyer buys a CBU of the product from another country, the product is in a ready-to-use state.

In the SDK (Semi Knocked Down), the exporters separate the goods and export the products through the SKD. In the SKD type, products are not all disassembled into parts, but partially assembled and partially kits to be assembled.

CKD (Completely Knocked Down), various components are delivered from suppliers around the world and manufactured in importing countries. This means that the completely disassembled kit after manufacturing will be assembled by the dealer or the consumer.

This paper focuses on purchasing LED luminaires in terms of SKD. First of all, take the three LEDLUCKY luminaires as an example to simply show you the main components of SKD that can be used in industrial lighting, office lighting, sports lighting, etc.

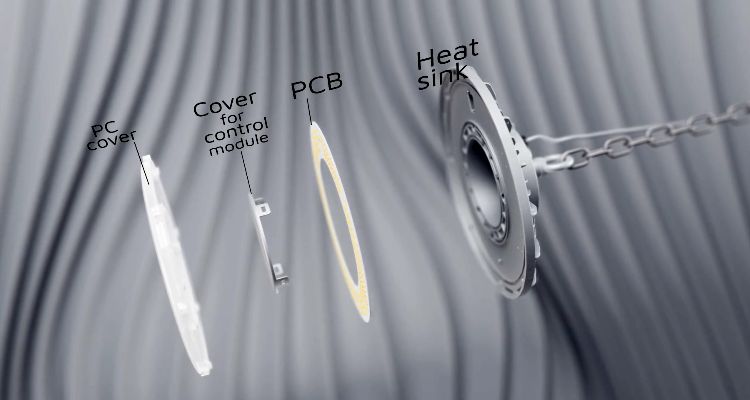

Highbay Light – Vista

Heatsink

Vista’s radiator uses the die-cast aluminum ADC 12 with excellent heat dissipation performance as the material. And use the fins to increase the radiator surface area, leaving enough room between the fins for the air to pass through and cool down faster. Finally, the surface spray powder coating further improves the heat dissipation capacity.

PCB

LED luminaires have the advantages of excellent energy efficiency, low cost, and maximum design flexibility, so they can be integrated into many lighting applications. Use several screws to tighten the PCB plate on the radiator.

Control module

Adapting the standard 4-pin ZHAGA interface, the Vista family is compatible with various open control modules. Such as PIR sensors, microwave motion sensors, etc. The plug-and-play design allows the most convenience for the end user to satisfy the project’s needs.

PC optics

The polycarbonate optic cover provides a vista with excellent light distribution, good uniformity, and a large luminous area, which also displays excellent performance in installation.

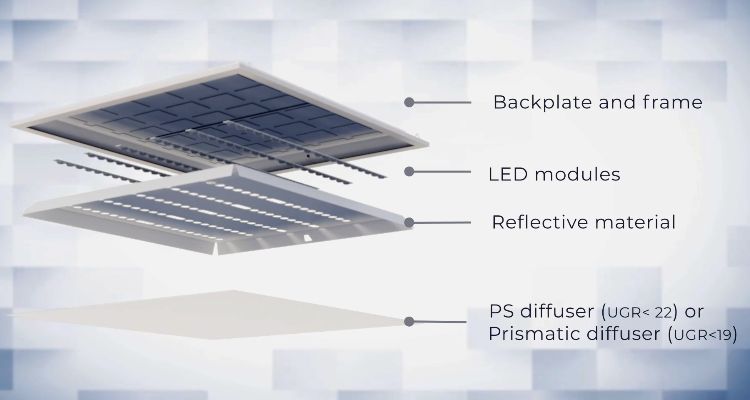

Panel Light – 180 lm/W Backlit Panel

Backboard and frame

The frame is part of the backbone of the entire panel light structure and is not easily twisted and bent. The frame also plays an important role in cooling the LED chip — which prolongs the lifetime of the whole luminaire up to 50,000hrs.

LED module

The light output of all LED chips will decrease after a period of time, which is measurable and predictable; in this case, this lifetime of panel light is 50000 H @ L 70 / B10. This means that the LED lamp maintains 70% of the initial lumen at 50,000 hours, and only 10% of the light fails to reach 70% lumen.

A PS diffuser or a prism diffuser

The function of this component is to scatter the light flux so that the light is distributed evenly (part of the composite diffusion plate can not only homogenize the light but also control the emission Angle). There is also a support backlight architecture that protects the underlying optical material from damage. LEDLUCKY This panel lamp can achieve a very low UGR (<19).

Stadium Light – Agility

Gearbox

In the same drive box, the power supply of 100W-900W output can be provided.

Mounting bracket

Support the whole lamp, which can be adjusted from various angles to meet the user’s needs.

Module

Modularity is the key design of Agility, and each module can be packaged separately during transportation. In addition, the power supply and accessories also support separate packaging.

Advantages Of SKD Lamps

Reduce the test and quality inspection steps

In SKD, testing and quality inspection work less than in CKD. This means that testing and quality testing take less time.

Reduce the space footprint

In cargo transportation, the transportation cost is usually calculated according to the space occupied by the volume of the article. Therefore, SKD has lower transportation costs than CBU.

Lower tariffs

Many governments impose taxes on imports with SKD less than CBU. Because SKD provides more jobs to importing countries (such as parts manufacturing, assembly, etc.), the government is willing to give more tariff concessions.

Reduce technical requirements

The technical requirements required for assembling the SKD lamps are not high. If you are an electrician, you can easily assemble them according to the relevant user manual. This reduces the cost of the buyer’s investment in specific machinery, equipment, technology, and skills.

In conclusion, SKD lamps are located between CBU with a high tax rate and CKD with higher technical requirements, which is an option with lower overall cost. Importers and consumers assemble different SKD parts according to their own habits, that is, lamps with different wattage, multiple control modes, and different CCT, to meet the needs of end users on different occasions, which is a more humanized performance of the consumer market., More and more governments are also supporting this model.